End-to-end microbiologically influenced corrosion solutions for offshore wind farm foundations, from inspections with X3 subsea ROV to corrosion risk analysis, that minimises operation and maintenance risks.

As data from operational offshore wind farms becomes available, the original design assumptions may be challenged by sometimes unpredictable reality at sea, particularly in the areas of foundations. For example, stagnant water may be a source of sulphate, leading to microbiologically influenced corrosion (MIC).

MIC is a relatively new phenomenon in offshore wind, partially because of the relatively young age of most offshore assets in this industry. As the quantity (and complexity) of wind turbines offshore grows, the need for a better understanding and management of MIC is needed. MIC is perhaps best known, for example, for helping to accelerate the decay of the famous wreck, The Titanic.

How does Intertek help offshore wind turbine operators understand and mitigate the risks of MIC on their valuable assets offshore?

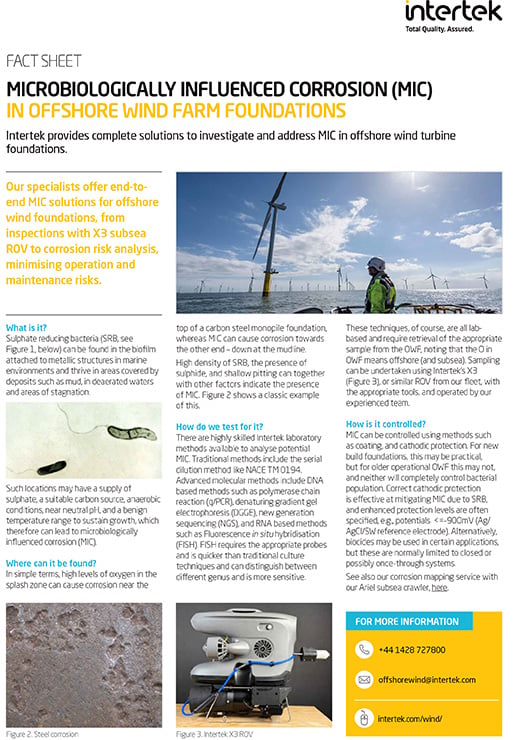

Using our own fleet of ROVs, we can take samples from both outside and (where permitted) inside monopiles and jackets, the foundations commonly used in offshore wind. Sampling can be undertaken using Intertek’s X3 or similar ROV from our fleet, with the appropriate tools, and operated by our experienced team.

Our Intertek Capcis team then provides expert analysis of the results and consultation on the mitigation strategies that offshore wind farms operation and maintenance teams (O&M) may take. Intertek utilizes traditional and advanced laboratory methods to analyse potential microbiologically influenced corrosion. Traditional methods include the serial dilution method such as NACE TM 0194 whereas advanced molecular techniques include DNA-based methods such as polymerase chain reaction (q/PCR) and RNA-based methods such as fluorescence in situ hybridisation (FISH).

This may lead to an assessment of remaining useful life based on further inspections such as material thickness inspection, subsea, weld inspection, or full corrosion mapping using Intertek’s innovative robotic tool. In addition to understanding the mechanics of the foundation, understanding the levels of oxygenation at different depths and in different scenarios, the reliability of J tube seals and other potential ‘leak’ sources are also important.

Microbiologically influenced corrosion can be controlled using methods such as coating and cathodic protection. For new build foundations, this may be practical, but for older operational OWF this may not, and neither will completely control bacterial population. Alternatively, biocides may be used in certain applications, but these are normally limited to closed or possibly once-through systems.

Contact us to learn more about Intertek's end-to-end MIC solutions for offshore wind foundations and how they can help you minimise operation and maintenance risks.